Operational Documents

- Work Order Sheet

- Outsourcing Sheet

- Costing Sheet

- Costing List

Chirix empowers you to efficiently run your shop floor, accurately plan your inventory and instantly meet delivery deadlines. You will also be able to monitor and manage your process better. Including management of customer orders, pre-planned production concept to identify the shortage materials and the delivery of ordered products as finished stocks. Chirix supports both Discrete Manufacturing (Semi Finished Goods) and Process Manufacturing (Finished Goods).

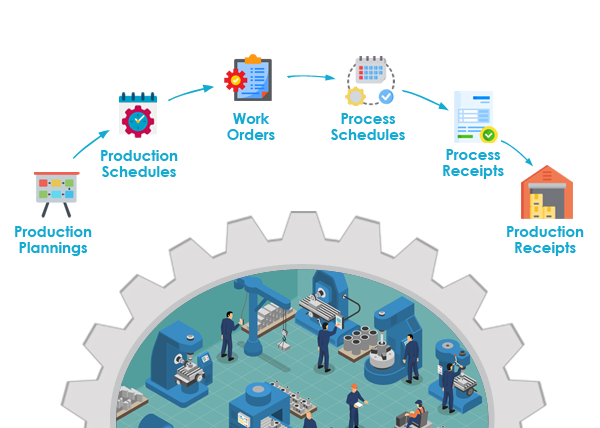

Chirix is used to track out the work order process and captures the detailed labor cost details and work order tracking information. Work order process schedule can be maintained and we can provide the service wise salary. Chirix solves a number of challenges and provides valuable benefits to the manufacturers looking to reduce the productivity cost to manage the production growth and increase the sales to gain aggressive returns. This module consists of functionalities like Production Planning, Production Scheduling, Raw Material Consumption, Bill of Material and to track daily production progress production forecasting & actual production reporting. Chirix integrated with all areas of the industry that provides the noticeable improvement of Purchase-Inventory-Production-Sales-Despatch.

Helps to improve the profitability of production, Chirix software features functionality to streamline.

Plant plays the key role in the production. Plant means the shop floor [Manufacturing Area]. Multiple plants can support in Chirix. We can restrict the plant visibility to other plant users.

Maintains Bill of Materials for finished and semi-finished products to enable planning of raw materials and for procurement.

Work Order will probably state the quantity of the product to be manufactured & raw materials used, list of process rate (per unit/per hour) and amount and Bill of Material of the product.

Chirix enables you to easily track your production process in Work Order and also can be able to monitor the wastage in each stage of production.

Chirix enables you to easily track progressive scrap at every operation and measure scrap tolerances, thereby facilitating more accurate production costs.

Chirix supports predefined process to track the production process. Chirix supports to combine two different semi-finished items manufacturing into a finished one.

Chirix enables to pre calculate the product cost i.e. materials cost and process cost to make quick decision of market selling rate includes profit and depreciation.

Chirix enables to check the cost of consumed materials which are used for the process and the whole production cost against the billing rate to check whether Gain or Loss.

Chirix supports manufacturing industries practice of planning the production earlier than the execution for the efficient manufacturing. Plan production across your organization by consolidating confirmed orders and forecast demand.

Chirix enables to scheduling the production plan for an individual product or a Customer order and also we can assign the start time and end time for the production. Production Schedule can be done based on the demand of the products and the capacity of storage place or warehouse in an organization.

In Process Scheduling we can schedule and monitor the multiple processes and resources. Process Schedule and process receipt helps to track down the processes.

Chirix helps to keep the minimum stock level at each production plant. We optimize store level demand forecasting for regular turn merchandise and promotional products.

Creates quote overdue work order list, overdue process list and allows the user to quickly Email or SMS requests to vendors.